Name Brand Wholesale & Closeout Tools

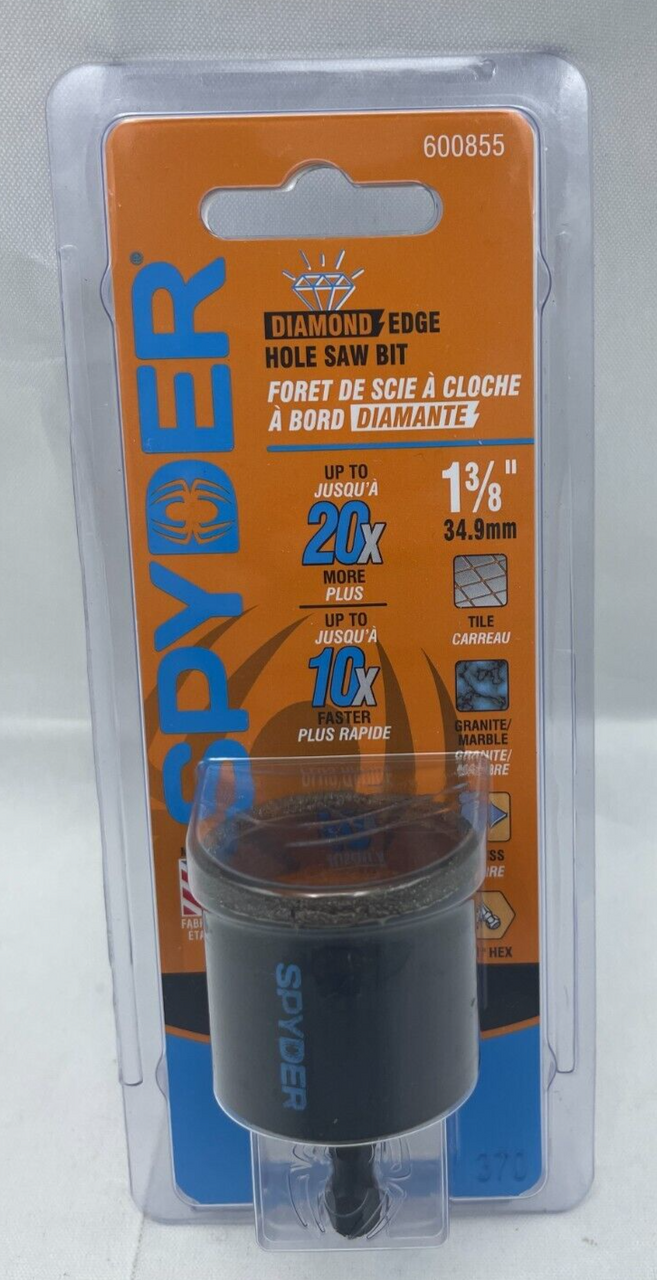

Spyder 1-3/8-in Diamond Edge Arbored Hole Saw Bit with Hex Drive 600855

Recommended

-

Spyder 3/8-in Diamond Carbide Tipped Hole Saw Arbor

MSRP:Now: $5.70Qty:1